Ukwelashwa kwesisekelo sesayithi

1. Ngaphambi kokubeka i-geomembrane ye-HDPE, isisekelo sokubeka kufanele sihlolwe ngokuphelele kanye neminyango efanele.Isisekelo sokubeka kufanele sibe siqinile futhi siyisicaba.Ngeke kube nezimpande zesihlahla, imfucumfucu, amatshe, izinhlayiya zikakhonkolo, amakhanda okuqinisa, ama-chips engilazi kanye nezinye izinsalela ezingase zilimaze i-geomembrane phakathi kokushona okuqondile okungama-25 mm.Sebenzisa i-wheel compactor ukuhlanganisa ukuze ukhiphe izimpawu zemoto, izinyathelo zezinyawo namaqhuqhuva aphansi.Ngaphezu kwalokho, amaqhuqhuva aphansi angaphezu kuka-12mm nawo azoqoshwa noma ahlanganiswe.

2. Uma i-HDPE geomembrane ibekwe ku-backfill, ukubumbana kokugcwaliswa kwangemuva akumele kube ngaphansi kwama-95%.

3.Isisekelo sesizinda ngeke singabi namanzi agelezayo, udaka, amachibi, izinsalela zezinto eziphilayo kanye nezinto eziyingozi ezingase zidale ukungcoliswa kwemvelo.Ikhona lesisekelo liyoba bushelelezi.Ngokuvamile, i-arc radius yayo akufanele ibe ngaphansi kuka-500 mm.

Izidingo zobuchwepheshe zokufakwa kwe-HDPE geomembrane.

1. Ukubekwa nokushiselwa kwe-HDPE geomembrane kufanele kwenziwe esimweni sezulu lapho izinga lokushisa lingaphezu kuka-5 ℃ futhi amandla omoya angaphansi kweBanga lesi-4 ngaphandle kwemvula noma iqhwa.

2. Inqubo yokwakha ye-HDPE geomembrane izokwenziwa ngohlelo olulandelayo: i-geomembrane laying → amajoyinti wokushisela ama-lapping → ukushisela → ukuhlola endaweni → ukulungisa → ukuhlola kabusha → ukugcwaliswa kabusha.

3. Ububanzi obudlulanayo bamalunga phakathi kolwelwesi akumele bube ngaphansi kuka-80mm.Ngokuvamile, isiqondiso sokuhlelwa okuhlanganyelwe sizolingana nomugqa omkhulu wokuthambeka, okungukuthi, uzohlelwa ngokuhambisana nesiqondiso somthambeko.

4. Ngesikhathi sokubekwa kwe-HDPE geomembrane, imibimbi yokwenziwa kufanele igwenywe ngangokunokwenzeka.Uma ubeka i-HDPE geomembrane, ukwakheka kokunwetshwa okubangelwa ukushintsha kwezinga lokushisa kuzogcinwa ngokuya ngebanga lokushintsha kwezinga lokushisa lasendaweni kanye nezidingo zokusebenza ze-HDPE geomembrane.Ngaphezu kwalokho, inani lokunwetshwa le-geomembrane lizogcinwa ngokuya ngendawo yesayithi kanye nokubekwa kwe-geomembrane ukuze ivumelane nokuhlaliswa okungalingani kwesisekelo.

5. Ngemuva kokuthi i-geomembrane ye-HDPE ibekwe, ukuhamba phezu kwe-membrane namathuluzi okuphatha kuzoncishiswa.Izinto ezingabangela ukulimala kwe-HDPE geomembrane akufanele zibekwe ku-geomembrane noma zithwalwe ku-geomembrane ukuze kugwenywe ukulimala kwengozi kulwelwesi lwe-HDPE.

6. Bonke abasebenzi abasendaweni yokwakha ifilimu ye-HDPE akufanele babheme, bagqoke izicathulo ezinezinzipho noma izicathulo ezinezithende eziqinile ezinesoli ukuze bahambe endaweni yefilimu, noma benze noma yimuphi umsebenzi ongonakalisa ifilimu engangenisi.

7. Ngemva kokubekwa kwe-geomembrane ye-HDPE nangaphambi kokuba ungqimba oluvikelayo lumbozwe, isikhwama sesihlabathi esingu-20-40Kg sizobekwa ekhoneni lolwelwesi njalo ngamamitha angu-2-5 ukuvimbela i-geomembrane ukuthi ingashaywa umoya.

8. I-geomembrane ye-HDPE izoba yemvelo futhi isondele kungqimba olusekelayo, futhi ngeke isongwe noma imiswe emoyeni.

9. Uma i-geomembrane yakhiwe ngezigaba, ungqimba olungaphezulu kufanele lumbozwe ngesikhathi ngemva kokubekwa, futhi isikhathi esiveziwe emoyeni akumele sidlule izinsuku ezingama-30.

Ukuma kwe-HDPE geomembrane kuzokwenziwa ngokuya ngomklamo.Ezindaweni ezinezindawo eziyinkimbinkimbi kuphrojekthi, iyunithi yokwakha izophakamisa ezinye izindlela zokubambelela, ezizokwenziwa ngemva kokuthola imvume yeyunithi yokuklama kanye neyunithi yokuqondisa.

Izidingo zokushisela i-HDPE geomembrane:

1. Indawo egqagqene ye-HDPE geomembrane weld ngeke ingabi nakungcola, isihlabathi, amanzi (kuhlanganise namazolo) nokunye ukungcola okuthinta ikhwalithi yokushisela, futhi izohlanzwa ngesikhathi sokushisela.

2. Ekuqaleni kwe-welding nsuku zonke (ekuseni nangemva kwekhefu lesidlo sasemini), ukuhlolwa kwe-welding kufanele kwenziwe esizeni kuqala, futhi ukushisela okusemthethweni kungenziwa kuphela ngemva kokufaneleka.

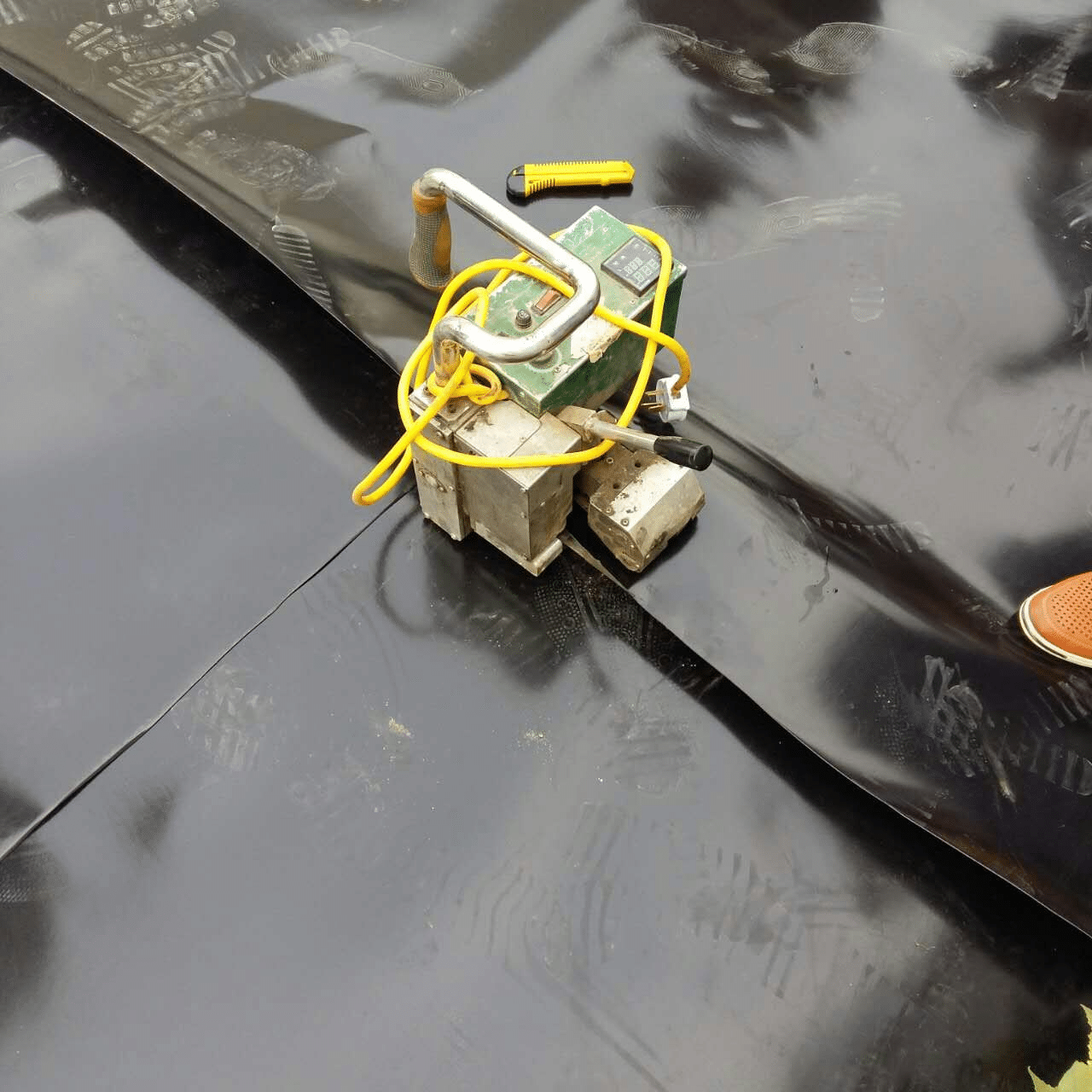

3. I-geomembrane ye-HDPE kufanele ihlanganiswe ngomshini wokushisela we-double track hot-melt, futhi i-extrusion welding noma i-hot-air gun welding kufanele isetshenziswe kuphela ezindaweni lapho umshini wokukhanda, ukumboza noma we-hot-melt awukwazi ukufinyelela khona.

4. Ngesikhathi sokwakhiwa, izinga lokushisa elisebenzayo kanye nesivinini somshini wokushisela kuzolungiswa futhi lilawulwe nganoma yisiphi isikhathi ngokusho kwezinga lokushisa kanye nezinto ezibonakalayo.

Ifilimu ye-5.HDPE e-weld izohlanganiswa iyonke, futhi ngeke kube khona ukushisela okungamanga, ukuthungatha okulahlekile noma ukuthungatha ngokweqile.Izendlalelo ezimbili ezixhunyiwe ze-HDPE geomembrane kufanele zifakwe isicaba futhi zibe mnene.

Ukulawulwa kwekhwalithi yokushisela

Ngokuqhubeka kokwakhiwa, kuyadingeka ukuthi uhlole ikhwalithi yokushisela yefilimu ye-HDPE ngesikhathi, futhi ulungise ukushisela ngesibhamu somoya oshisayo noma isibhamu seplastiki sokushisela nganoma yisiphi isikhathi ngenxa yezingxenye zokushisela ezingekho kanye nezingxenye zokushisela ezingalungile.Izindlela eziqondile zimi kanje:

1.Ukuhlola kwenziwa ngezinyathelo ezintathu, okungukuthi ukuhlola okubonakalayo, ukuhlolwa kokwehla kwamandla emali kanye nokuhlolwa komonakalo.

2. Ukuhlola okubukwayo: hlola ukuthi ingabe amashisela amabili ayisicaba, acacile, awashwabanisi, asobala, awanawo ama-slag, amabhamuza, indawo evuzayo, indawo encibilikayo noma ubuhlalu obushiselayo.

Ukuhlola okubonakalayo ikakhulukazi ukuhlola ngokucophelela ukubukeka kwe-geomembrane ebekiwe, ikhwalithi ye-weld, i-welding emise okwe-T, imfucumfucu ye-substrate, njll. Bonke abasebenzi bokwakha bayokwenza lo msebenzi kuzo zonke izinqubo zokwakha.

3. Ngaphezu kokuhlola okubukwayo, ukuhlolwa kwe-vacuum kuzokwamukelwa ukuze kuqine wonke ama-welds, futhi ukuzihlola kuzoqiniswa izingxenye ezingakwazi ukuhlolwa nge-vacuum.

4. Amandla okwehla kwamandla emali atholwe umfutho wokwehla kwamandla emali ngu-0.25Mpa, futhi akukho ukuvuza komoya imizuzu emi-2.Uma kucatshangelwa ukuthi izinto eziboshiwe zithambile futhi kulula ukonakala, ukwehla kwengcindezi okuvumelekile kungu-20%

5. Lapho wenza ukuhlolwa okuqinile kusampula ethathwe ku-double rail weld, izinga liwukuthi i-weld ayidabuki kodwa umama uyadatshulwa futhi alimale ngesikhathi sokuhlolwa kwekhasi nokugunda.Ngalesi sikhathi, i-welding ifanelekile.Uma isampula ingafaneleki, ucezu lwesibili luzothathwa ku-weld yangempela.Uma izingcezu ezintathu zingafanelekile, yonke i-weld izosetshenzwa kabusha.

6. Amasampula aphumelele isivivinyo azothunyelwa kuMnikazi, kuSonkontileka Jikelele kanye namayunithi afanelekile ukuze afakwe.

7. Amaphutha atholakala ekuhloleni okubonakalayo, ukutholwa kokwehla kwamandla emali kanye nokuhlolwa komonakalo kuzolungiswa ngesikhathi.Lezo ezingeke zilungiswe ngokushesha zizomakwa ukuze kuvinjelwe ukushiywa ngesikhathi sokulungiswa.

8. Ekuhlolweni kokubukeka, uma kwenzeka kuba namaphutha njengezimbobo kulwelwesi kanye nokushisela okungekho, ukushisela okungalungile kanye nokulimala ngesikhathi sokushisela, isisekelo sensimbi esisha siyosetshenziswa ukulungisa ngesikhathi, futhi uhlangothi ngalunye lwesibazi esilungisiwe luyodlula ingxenye ilimele ngo-10-20cm.Yenza amarekhodi.

9. Ukuze kulungiswe i-weld, ukuhlolwa okubonakalayo okunemininingwane kuyokwenziwa ngokujwayelekile, futhi ukukhululwa kuyokwenziwa ngemva kokuba ukulungiswa kuqinisekisiwe ukuthi kuthembekile.

Isikhathi sokuthumela: Dec-14-2022